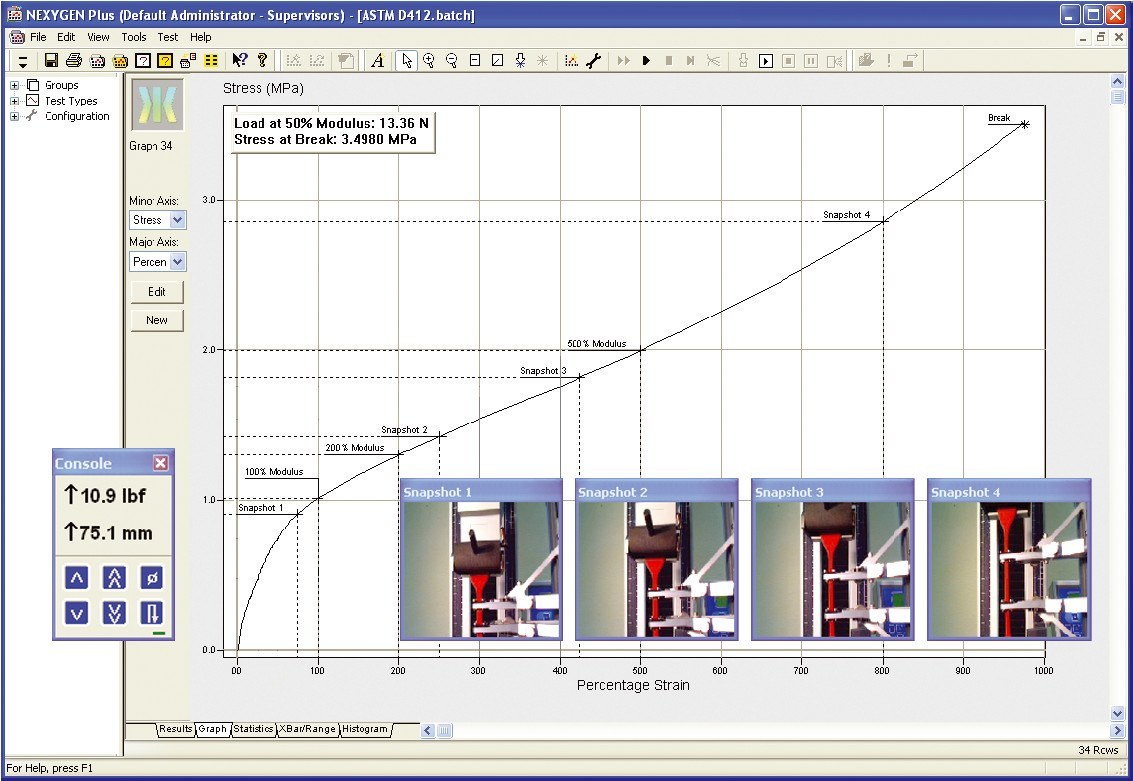

- The mechanical tests were performed according to ASTM D-882 standard test (ASTM, 1992) and the results were analyzed using NEXYGEN Plus software. Polymer composites of rectangular shape of dimension 25 × 100 mm were used for the determination of all mechanical parameters.

- NEXYGEN Plus 2.1. NEXYGEN Plus 1.1. NEXYGENPlus is a powerful material test and data analysis program. It allows the operator to control.

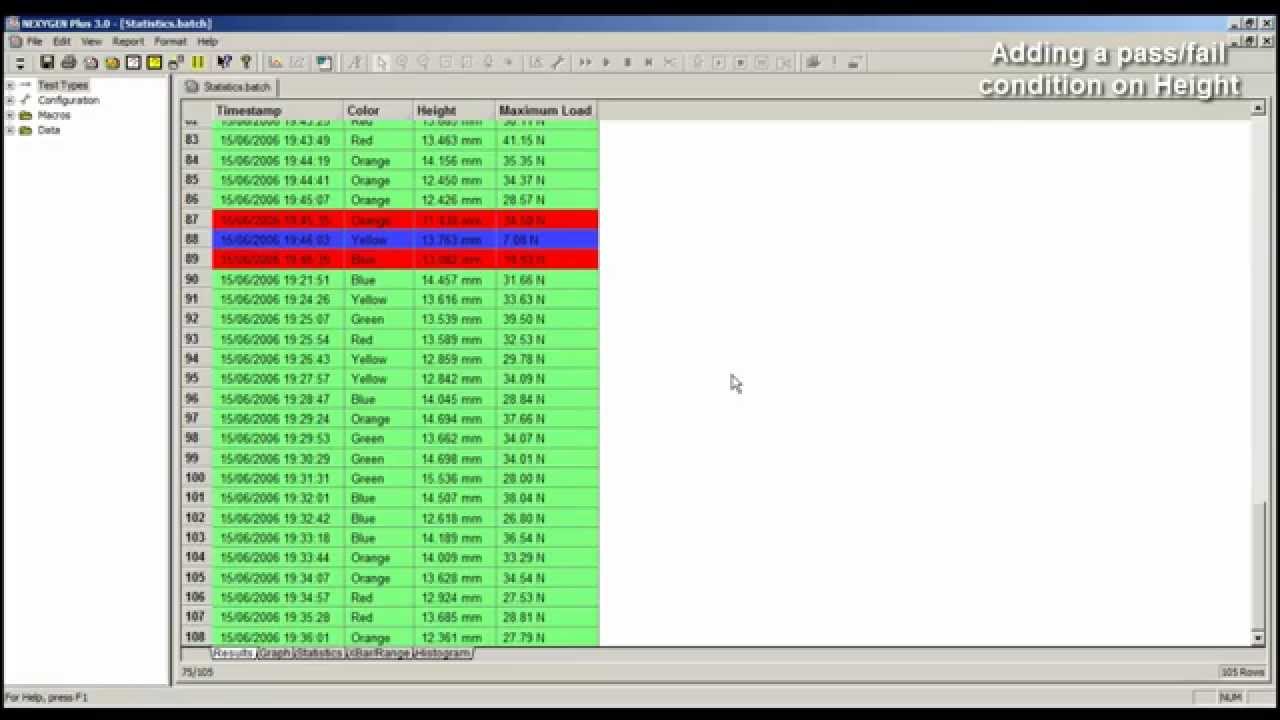

- 40/0783, Nexygen Plus 4 Software. This extraordinary flexible and easy-to-use materials testing software allows the operator to control and monitor all aspects of the system from a single front end, ensuring fast, reliable and powerful testing and data analysis for a variety of test types such as tensile, compression, peeling, tearing, creep.

- Nexygen plus NEXYGENPlus is a flexible, easy to use material testing software that allows operator to control and monitor all aspects of the testing system from a single interface. This software is part of the Lloyd Plus Series Material Testing System which offers the user extensive library of pre-defined test setups based on international.

Data Analysis and Materials Testing Software NEXYGENPlus multi-lingual materials testing software is the hub of the Lloyd Instruments materials testing system. This extraordinarily easy to use and flexible software, allows the operator to control and monitor all aspects of the system from a single front end, ensuring fast, reliable and powerful testing and data analysis for tensile.

In the present generation, nanoparticles of transition metal oxides (TMOs) are the main areas of materials research due to their wide applications in many areas. In spite of these TMOs, zinc oxide nanoparticles are used in numerous applications like UV absorption, antibacterial treatment, and so forth [

Nextgen Material Testing

Nexygen Plus 3 User Manual

In this current paper, initially, zinc oxide (ZnO) nanoparticles are prepared by precipitation method and then doped into the PVA matrix by coagulation technique to prepare the polymer nanocomposites by utilizing simple solvent casting method. The crystalline and morphological properties were investigated using X-ray diffraction (XRD), FTIR, scanning electron microscopy (SEM), and energy-dispersive X-ray spectroscopy (EDAX). The information regarding the optical properties and Urbach energies of the films is studied using UV/visible spectroscopy. The mechanical properties were investigated using universal testing machine (UTM).